Introduction to Stainless Steel Finishes

Stainless steel is a popular choice for kitchen appliances, tools, and utensils. Although stainless steel is extremely durable and resistant to corrosion, it can still look dull or scratched over time. To keep it looking its best, stainless steel is available in several different finishes.

The two most popular finishes are brushed and polished stainless steel. While both finishes offer the same level of protection and durability, there are some important differences between the two.

In this guide, we will discuss the differences between brushed and polished stainless steel, as well as the advantages and disadvantages of each. We will also provide a cost comparison and maintenance tips so that you can make an educated decision when choosing the right finish for your needs.

Table of Contents

What is Brushed Stainless Steel?

Brushed stainless steel included 180#,240#,320#,400#,it is a type of finish that has been sanded or textured to give it a muted, satin-like appearance. It is often used in place of traditional polished finishes as it gives a more subtle, natural effect. It is created by brushing the steel with an abrasive material like sandpaper or aluminum oxide to create the textured finish. The finish can be applied to sheets, strip, plates, and other forms.

The brushed stainless steel finish offers many benefits compared to polished finishes. It is more durable, easier to clean, and more resistant to fingerprints, smudges, and scratches. The muted look also fits into many styles better than the glossy look of a polished finish.

Brushed stainless steel tube process: When using a stainless steel tube polishing machine for polishing, the polishing personnel must first understand the structure and requirements of the required polishing equipment, master the safety operating procedures, and prepare the necessary tools. Polishing employees wear necessary labor protection equipment, and there are no less than two operators. The surrounding environment meets the requirements and can be ventilated.

- Carry out surface inspection on the stainless steel pipes transferred to the polishing process, such as whether there are missing welds in the welds, weld penetration, uneven depth of solder joints, too far away from the joints, local depressions, uneven butt joints, and deep welds. Scratches, bruises, serious deformations and other defects that cannot be remedied in this process, if there are above-mentioned defects, they should be returned to the previous process for repair. If there are no above-mentioned defects, enter this polishing process.

- Coarse grinding, use 600# abrasive belt to grind on the surface of the stainless steel pipe. The goal of this process is to remove the solder joints left by the welding of the workpiece and the bruises that occur in the pipe making process to achieve a round weld. The corners are preliminarily formed, and there are basically no large scratches or bruises on the horizontal and vertical surfaces. After this step, the roughness of the sanded surface of the stainless steel tube should reach R0.8mm. Pay attention to the inclination angle of the grinding wheel in the polishing machine and control the pressure of the grinding wheel on the stainless steel pipe during the polishing process. Generally speaking, it is more moderate to be in a straight line with the thrown surface!

- Semi-fine grinding, use 800# grinding wheel to repeatedly polish the stainless steel tube according to the previous rough grinding method, mainly to correct the seams that appear in the previous process and to further finely grind the impressions produced after rough grinding The marks left by the process should be polished repeatedly to achieve no scratches on the surface of the workpiece and basically brighten. The surface roughness of this process should be able to reach R0.4mm. (Be careful not to create new scratches and bruises in this process, because such defects cannot be repaired in subsequent processes.)

- In addition, it is necessary to pay attention to the replacement of the abrasive belt to ensure that the abrasive belt can rotate smoothly on the sponge wheel, so as to achieve the purpose of uniformly polishing the stainless steel tube.

What is Polished Stainless Steel?

Polished stainless steel included 400#,600#,8k,it is a type of steel finish that has a high-gloss sheen and a very reflective quality. It is made by polishing the metal surface with an abrasive material until it is smooth and looks shiny. This type of stainless steel finish provides a very stylish and contemporary look, and has become increasingly popular in many applications.

The process to create polished stainless steel involves first removing the surface layer of the metal. This is achieved by using a grinding wheel or abrasive pad and then polishing it until the desired finish is achieved. The polishing process is done by hand or using a machine, depending on the size and shape of the object being polished. Depending on the finish desired, the polishing may be done in multiple steps to achieve the desired effect.

Polished stainless steel has several advantages as a finish. Firstly, it is a very strong and durable finish and will not tarnish or corrode over time. Secondly, it is easy to clean and maintain, requiring only occasional wiping with a damp cloth. Lastly, polished stainless steel provides a sleek and modern aesthetic that can be used in a variety of applications, from kitchen sinks to hardware fixtures.

Mirror polishing mass production processs

The main purpose of the bright polishing part is to mirror the stainless steel sanding tube that has been polished in the rough grinding stage to achieve the purpose of the mirror surface.

- For fine grinding, the 1000# abrasive belt is mainly used to correct and grind the fine lines that appear in the previous process. The grinding method is the same as above. The goal of this process is to polish the weld seam of the stainless steel pipe until it basically disappears, so that the surface of the stainless steel pipe is further brightened. The polished pipe through this process should be basically close to the mirror effect, and the surface roughness of the workpiece should be able to reach R0.1mm

- Visually inspect the stainless steel pipes that enter this process in the previous step, and check to confirm whether there is any leakage and grinding to 1000#, all solder joints are not completely polished, there are traces of rough grinding, and the protective film is seriously damaged. If there are such problems, it is necessary to return to re-grind or repair.

- Mirror surface. Use the high-speed motor to drive the wool wheel (available on the market), and use the Polishing wax to mirror the polishing method in front of it. The main purpose of this process is to mirror-polish the stainless steel tube after the polishing of the previous processes. rather than further polishing. Be careful not to rub the polishing wax on the covering film on the surface of the stainless steel tube during this step, and be careful not to damage the covering film.

- Polishing. This process is the last process of mirror polishing. Use a clean cotton cloth wheel to rub the surface of the tube after the mirror surface, and clean and polish the tube after all the previous processes are completed. The goal of this process is to make the surface of the tube unrecognizable of welding traces, and to polish the waxed and polished tube so that the brightness reaches a specular reflection height of 8K, and there is almost no difference between the polished part and the unpolished part of the stainless steel tube . Achieve a full mirror effect.

Appearance Comparison

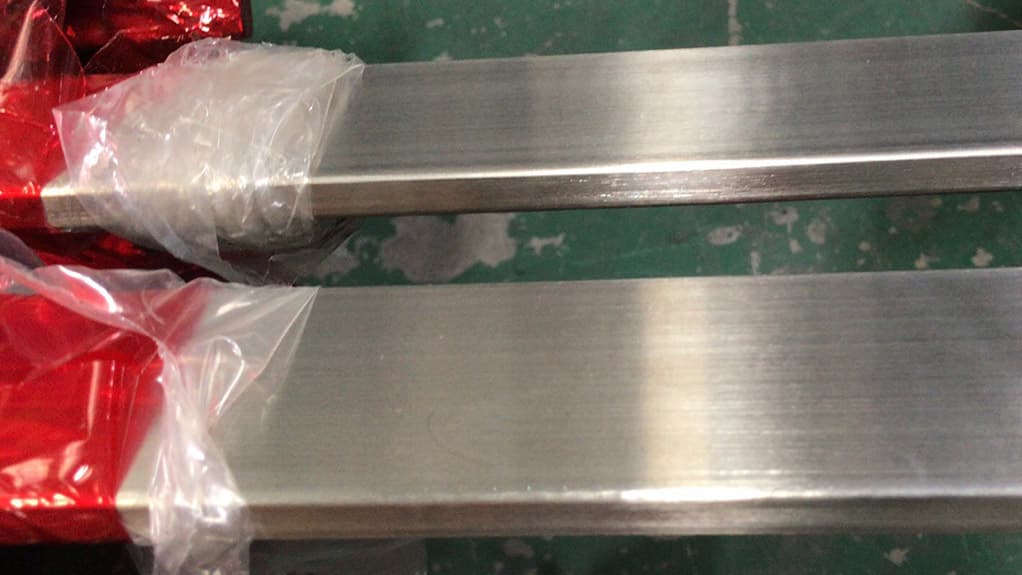

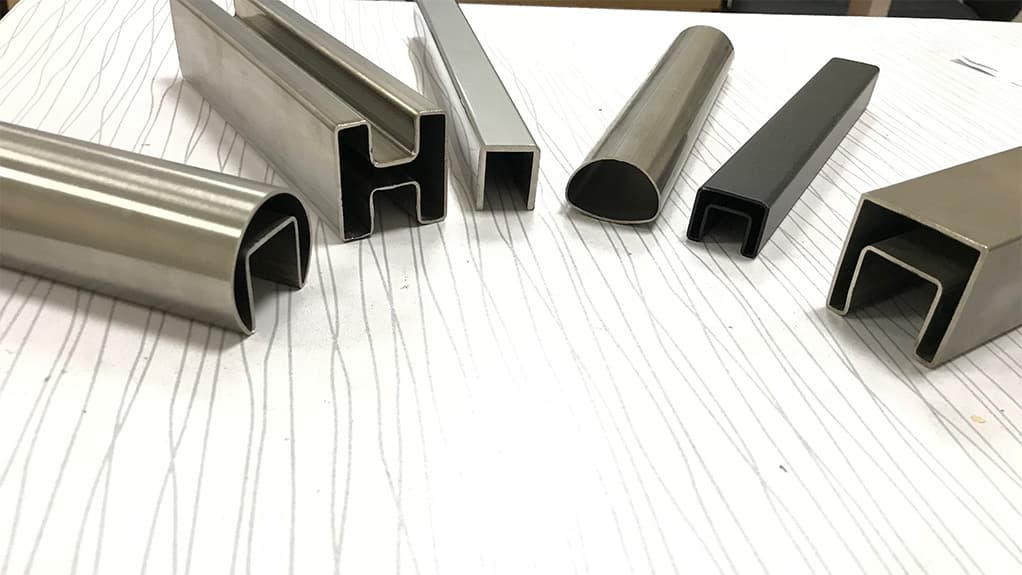

One of the key differences between brushed and polished stainless steel is in their appearances. Brushed stainless steel has a slightly granular texture that has a pleasing, modern look. It doesn’t grab attention, but still adds some visual interest to the material. On the other hand, polished stainless steel has a glossy, reflective shine that can be quite eye-catching. To see the difference in appearance, check out the images below:

- Brushed Stainless Steel

- Polished Stainless Steel

Special Considerations

Stainless steel is a material which is greatly affected by the environment in which it is placed. Different conditions such as temperature, humidity, and air quality can all have an impact on the appearance of brushed and polished stainless steel surfaces.

For example, elevated temperatures can cause stainless steel to discolor or tarnish, while high-humidity environments can lead to rust in some cases. Additionally, low-quality air can cause corrosion over time on both brushed and polished stainless steel surfaces.

It is important to be aware of these potential issues when placing stainless steel surfaces, particularly in outdoor environments such as balconies, patios, and other areas exposed to the elements.

Care and Maintenance of Brushed and Polished Stainless Steel

When it comes to stainless steel, the most important thing is proper maintenance and care. Both brushed and polished stainless steel require special attention in order to last.

If you have brushed stainless steel, it’s important to remember that brushing is done using an abrasive material. This means that the surface of the steel is highly susceptible to scratches and other damage. To avoid this, always use soft cloths or sponges when cleaning the surface and never use any harsh abrasive material. Additionally, regular cleaning with a non-abrasive cleaner should help keep your brushed stainless steel looking its best.

Polished stainless steel requires less maintenance than brushed stainless steel. However, it does need to be wiped down regularly and it’s important to avoid using harsh cleaners that can strip away the polish. For best results, use a soft microfiber cloth dampened with warm water and mild detergent. Avoid using any cleaning materials with strong alkaline or acidic properties as these could cause damage to the stainless steel.

To recap, brushed stainless steel requires gentle cleaning with soft cloths and a mild cleanser, while polished stainless steel needs regular dusting and gentle cleaning with a soft cloth.

Comparing Brushed and Polished Stainless Steel

When you’re choosing the finish for your stainless steel, you want to know the difference between a brushed and polished finish. Here we compare both brushed and polished stainless steel, using the topics discussed previously, to help you decide which finish is right for your application.

Brushed stainless steel has a matte-like finish and contains a directional grain running along its surface. This gives it a unique texture that stands out in modern designs. Its directional grain also gives it a slight advantage in durability compared to polished stainless steel.

Polished stainless steel, on the other hand, has a bright, shiny finish. It tends to reflect more light than brushed steel, making it an excellent choice for decorative applications where the look and feel of the material are important. However, its glossy finish can make it more prone to fingerprints, smudges, and other forms of wear and tear.

The cost of the two finishes is also different. Generally, brushed stainless steel is more expensive than polished stainless steel, as it requires more labor to achieve the same finish. If you’re looking to save money, then polished stainless steel may be the right choice for you.

Each type of finish offers advantages and disadvantages, so it’s important to consider the pros and cons when deciding which is best for you. Brushed stainless steel can add a unique texture to your design, but is more costly. Polished stainless steel is less expensive but may show signs of wear sooner.

Pros and Cons

When it comes to brushed or polished stainless steel, both finishes have their own set of advantages and disadvantages. Here are some of the pros and cons of each finish.

Brushed Stainless Steel

- Pros: Brushed stainless steel is a durable and affordable option for both commercial and residential use. It’s also easy to maintain, and its textured surface helps hide fingerprints and smudges.

- Cons: It can be difficult to keep clean and maintain its sheen over time. If not properly maintained, its surface can get scratched and show wear.

Polished Stainless Steel

- Pros: Polished stainless steel is extremely attractive and highly reflective, which makes it great for decorative uses. Its finish also helps protect it from scratches and smudges, and it’s easy to clean.

- Cons: It’s more expensive than brushed stainless steel, and its reflective surface may make it difficult to maintain its original look if not properly taken care of.

Applications of Brushed and Polished Stainless Steel

Brushed stainless steel has a matte-like look. It is often used in commercial and residential applications because of its durability and its modern, attractive look. Its functionality in commercial applications includes elevator doors, counters, kitchen appliances, and wall panels. In residential applications, brushed stainless steel can be found in kitchen hardware, door handles, and architectural details.

Polished stainless steel is characterized by its shiny, mirror-like appearance. Similar to brushed stainless steel, it is also found in virtually all commercial and residential applications. It is often used for accent pieces, such as display cases, or for larger pieces, like exterior columns or trim. Polished stainless steel is also used for interior details, such as vaulted ceilings, stair rails, and cabinet fronts.

In general, brushed stainless steel is the preferred choice for outdoor and wet environments, while polished stainless steel is preferred for indoor and dry locations. However, both finishes can be used in a variety of applications, depending on the desired design aesthetic.

Cost Comparison & Cost Savings

When it comes to the cost of brushed vs. polished stainless steel, the materials can vary in price. Generally speaking, brushed stainless steel tends to be more expensive. This is due to the labor-intensive brushing process that creates the finish on the steel.

Polished stainless steel can be more cost-effective since it does not require as much labor or material to create a mirror-like finish. Both types of stainless steel come with a variety of pricing options, depending on your project.

When deciding between brushed and polished stainless steel, the overall cost savings may come down to the application you are using it for. For instance, if you’re looking for a more rustic look, then brushed stainless steel may be a more cost-effective choice. On the other hand, if you are looking for a sleek, high-end look, polished stainless steel may be a better option.

It’s important to consider the type of environment the stainless steel will be placed in and the type of maintenance it will need. If you are willing to invest a bit more upfront, a higher grade of stainless steel may make it easier to care for and prevent from corroding over time.

Specialty Finishes

When it comes to stainless steel, there are a range of specialty finishes that differ from the brushed and polished finishes. These unique finishes can be applied to create an interesting visual effect in high traffic areas or commercial applications.

These specialty finishes include:

- Hammered

- Flamed

- Textured

- Satin

Hammered surfaces have a distinctive design that gives it a unique look, while the flamed finish is a matte-like finish that is created by using a heat treatment process. Textured finishes are created with different types of tools and techniques, like brushing and polishing. Lastly, a satin finish is a dull non-reflective matte finish that is commonly used in kitchen areas.

These specialty stainless steel finishes provide a unique aesthetic compared to the traditional brushed and polished finishes.

Summary & Conclusion

Having discussed the various differences between brushed and polished stainless steel, it is clear that each style has its own unique advantages. Brushed stainless steel can offer a classic, warm look that doesn’t draw attention, while polished stainless steel can provide an eye-catching, modern shine accompanied by a cleaning ease. The choice of finish ultimately boils down to personal preference and the application it will be used for.

Both brushed and polished stainless steel require regular maintenance in order to maintain their appearance and prolong their shelf life. Cleaning can be done with mild soap and water or specialized cleaners designed for stainless steel finishes. Specialty finishes such as hammered or satin can also be considered for an interesting and unique look.

In conclusion, when deciding between brushed and polished stainless steel, it is important to consider the pros and cons of each finish. Both styles offer great benefits and can easily be maintained with proper care. It is also important to consider the cost of the finishes and whether or not it is worth investing in either one. Ultimately, the decision comes down to individual preference and what kind of look or feel you are going for.

Brushed vs Polished Stainless Steel FAQs

1. Q: What is brushed stainless steel?

A: Brushed stainless steel is made by brushing the surface with a special abrasive pad or brush, creating a smooth semi-reflective finish that highlights the natural look of the metal. It can also be referred to as brushed, satin, or dull stainless steel.

2. Q: What is polished stainless steel?

A: Polished stainless steel is an ultra-smooth mirror finish that is achieved by using fine grinding and polishing materials. This finish gives stainless steel a shiny look and brings out its luster.

3. Q: How does brushed stainless steel look in comparison to polished stainless steel?

A: Brushed stainless steel has a matte finish that appears rough and is not reflective like polished stainless steel. Polished stainless steel is smooth, bright, and has a reflective surface.

4. Q: What are the benefits of using brushed stainless steel?

A: Brushed stainless steel provides a unique look and feel that still looks modern and elegant. It is resistant to fingerprints and other marks, and it is also more resistant to corrosion caused by exposure to certain liquids, such as saltwater and acidic foods and beverages.

5. Q: What about the advantages of polished stainless steel?

A: Polished stainless steel provides a luxurious look and is highly resistant to tarnishing over time. It works well in both indoor and outdoor settings and it can be easily wiped clean with a damp cloth.

6. Q: What are some common applications for brushed and polished stainless steel?

A: Brushed stainless steel is often used in commercial and residential kitchens for countertops, backsplashes, and other decorations. It is also used in public spaces for appearance and durability. Polished stainless steel is used in bathrooms, kitchens, and living rooms to provide an elegant and modern appeal.

7. Q: What is the cost comparison between brushed and polished stainless steel?

A: While the initial cost of polished stainless steel is usually more than the cost of brushed stainless steel, in the long run it may be worth the investment. Polished stainless steel is more durable and easier to maintain, which could result in cost savings over time.