Comparison Table

| Material | Pros | Cons | Best Used For | Maintenance |

|---|---|---|---|---|

| Carbon Steel | Strong, durable, inexpensive | Low corrosion resistance | Indoor railings | Minor paint touch-up |

| 304-Grade Stainless Steel | Resistant to ordinary rust and corrosion | Can corrode in chlorinated or salty environments | Indoor or protected railings; non-harsh outdoor environments | Regular cleaning with soap and water |

| 316-Grade Stainless Steel | Highest corrosion resistance | More expensive, can tarnish over time | Outdoor or extreme environments; industrial uses | Virtually no maintenance |

Table of Contents

Introduction

Welcome to the world of home decor! Today, we’re going to delve into an often overlooked but crucial aspect of your home’s aesthetic – the railing system. More specifically, we’re going to focus on steel railing systems. Why steel, you ask? Well, let’s find out!

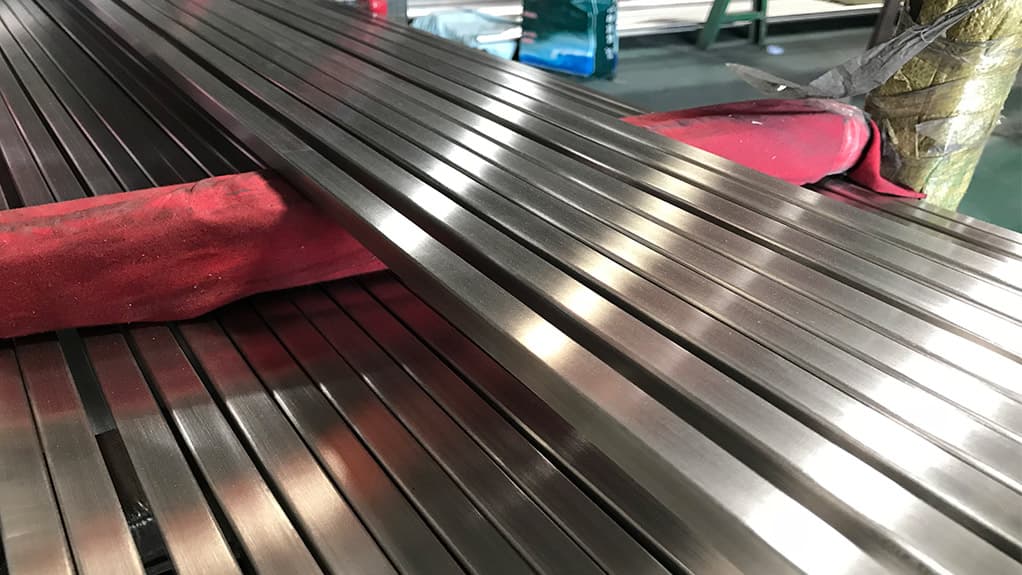

Steel is a versatile material that can adapt to a variety of aesthetics, whether you’re going for a sleek, modern look or a more traditional, formal vibe. But the beauty of steel goes beyond its looks. It’s also incredibly durable and long-lasting, making it a cost-effective choice in the long run.

Choosing the right material for your steel railing system can seem daunting, but don’t worry! We’re here to guide you through the process. With the help of Unity Metal, a leading manufacturer of stainless steel railings, we’ll explore the different types of steel and their applications, and help you make an informed decision.

The Advantages of Steel Railing Systems

When it comes to railing systems, steel is often the material of choice. Its superior strength and toughness make it a reliable choice for both indoor and outdoor applications. But the benefits of steel don’t stop there.

Steel railing systems offer tremendous aesthetic versatility. They can look sleek and modern or formal and traditional, depending on your design preferences. This means that no matter your home’s style, there’s a steel railing system that can complement it perfectly.

In addition to its aesthetic versatility, steel is also extremely durable. It can withstand high traffic and harsh environmental conditions, making it a long-lasting choice. This durability translates into cost-effectiveness over time. While the initial cost of a steel railing system might be higher than other materials, its longevity and low maintenance requirements make it a smart investment in the long run.

Steel vs. Aluminum Railing Systems

When choosing a material for your railing system, you might find yourself torn between steel and aluminum. Both materials have their merits, but there are some key differences to consider.

Steel is often preferred over aluminum due to its superior strength and toughness. This means that steel railing systems are more durable and can withstand more wear and tear than their aluminum counterparts. This is particularly important in high-traffic areas where the railing system will be subject to frequent use.

On the other hand, aluminum is more prone to surface scratches and dents. This can make it more challenging to maintain and keep looking its best. Additionally, from a design perspective, aluminum railings require more supports than steel, which can limit your design options.

Types of Steel for Railing Systems

When it comes to steel railing systems, there are three main types of steel to consider: carbon steel, 304-grade stainless steel, and 316-grade stainless steel. Each type has its strengths and weaknesses, and understanding these can help you make the best choice for your specific needs.

Carbon Steel is strong, durable, and relatively inexpensive. However, it has low corrosion resistance, making it best suited for indoor railings. Regular maintenance, such as minor paint touch-ups, can help keep carbon steel railings looking their best.

304-Grade Stainless Steel is resistant to ordinary rust and corrosion, making it a good choice for both indoor and protected outdoor railings. However, it can corrode in chlorinated or salty environments. Regular cleaning with soap and water can help maintain its appearance.

316-Grade Stainless Steel offers the highest corrosion resistance, making it the best choice for outdoor or extreme environments. It is more expensive than the other types of steel and can tarnish over time, but it requires virtually no maintenance.

Factors to Consider When Selecting Railing Materials

When choosing a material for your steel railing system, there are several factors to consider. These include the environment and location of the railing system, the level of traffic it will be exposed to, the expected level of maintenance, and your project budget.

The environment and location of the railing system are crucial factors to consider. For instance, if the railing system will be located outdoors, you’ll need a material that can withstand the elements. In this case, 316-grade stainless steel would be a good choice.

The level of traffic the railing will be exposed to is another important factor. High-traffic areas require durable materials that can withstand frequent use. Here, both carbon steel and 304-grade stainless steel would be suitable choices.

The Importance of Maintenance

Maintenance is a key factor to consider when choosing a material for your railing system. Different materials require different levels of maintenance, and understanding these requirements can help you make an informed decision.

Stainless steel, for instance, is relatively low-maintenance. Regular cleaning with warm water and a soft cloth can keep it looking its best. For stubborn stains, an organic solvent such as acetone or mineral spirits can be used.

On the other hand, carbon steel requires more attention. Maintenance crews will need to quickly repair nicks and scratches using touch-up paint to avoid corrosion. A long-term maintenance plan, which includes regular repainting or replacement of the protective coating, is nearly required.

Budget Considerations

Finally, budget is an important factor to consider when choosing the right railing material for your project. While it might be tempting to choose the least expensive material, it’s important to consider the long-term cost of ownership.

Choosing a less expensive material or finish might save money upfront, but it can prove costly in the long run. Future maintenance, cleaning, painting, and upkeep costs can add up over time. Therefore, it’s wise to consider these future costs when choosing a material for your railing system.

Conclusion

Choosing the right material for your steel railing system is a crucial decision that can impact the aesthetics, functionality, and longevity of your railing. With the help of Unity Metal, we hope this guide has provided you with the knowledge and confidence to make an informed decision. Remember, the perfect railing system is one that not only looks great but also stands the test of time.

FAQs

1. What is the best material for an outdoor steel railing system?

316-Grade Stainless Steel is the best choice for outdoor or extreme environments due to its high corrosion resistance.

2. What is the most cost-effective material for a steel railing system?

While the initial cost may be higher, steel is a cost-effective choice in the long run due to its durability and low maintenance requirements.

3. What is the best material for a high-traffic indoor railing system?

304-Grade Stainless Steel is a good choice for high-traffic indoor areas due to its durability and ease of maintenance.

4. What type of steel requires the least maintenance?

316-Grade Stainless Steel requires virtually no maintenance, making it a great choice for those seeking a low-maintenance option.

5. What factors should I consider when choosing a material for my steel railing system?

Consider the environment and location of the railing system, the level of traffic it will be exposed to, the expected level of maintenance, and your project budget.

*Note: All information is based on data from Unity Metal and Wikipedia.